Determining friction coefficients directly at the customers’ location

The VDI-directive 2700 sheet 14 or DIN EN 12195 part 1 describe test methods for the determination of friction coefficients which are required for the calculation of friction forces and for the design of load securing measures.

The sliding friction coefficient is relevant for load safety. It is significantly influenced by the number and size of friction efficient contact areas between the loading area or the under layer, such as anti-slip-mat, and cargo. As friction is defined as resistance against shifting of intermeshed objects, the sliding friction coefficient is generally dependant on all parameters which influence the efficiency of the intermeshing. These parameters are roughness of the involved contact areas, softness and flexibility of the contact areas, pressure, temperature behaviour, humidity, wetting of the contact areas with for example water (rain, also snow and ice) oil, grease and leaks, dirt and more.

The knowledge of the friction coefficients significantly simplifies the load securing. Doubling the coefficient of sliding friction results in a reduction of the lashing belts to one quarter. Contact us for more information!

Tests of Friction Coefficients

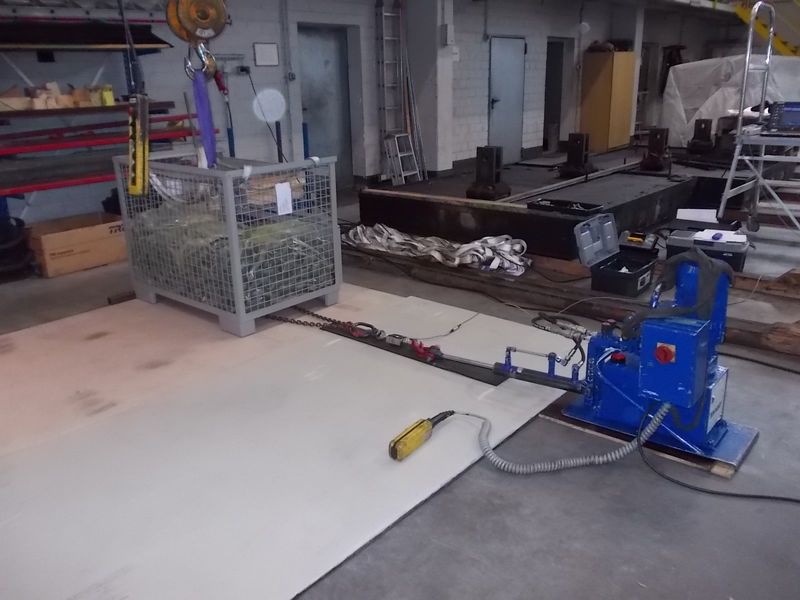

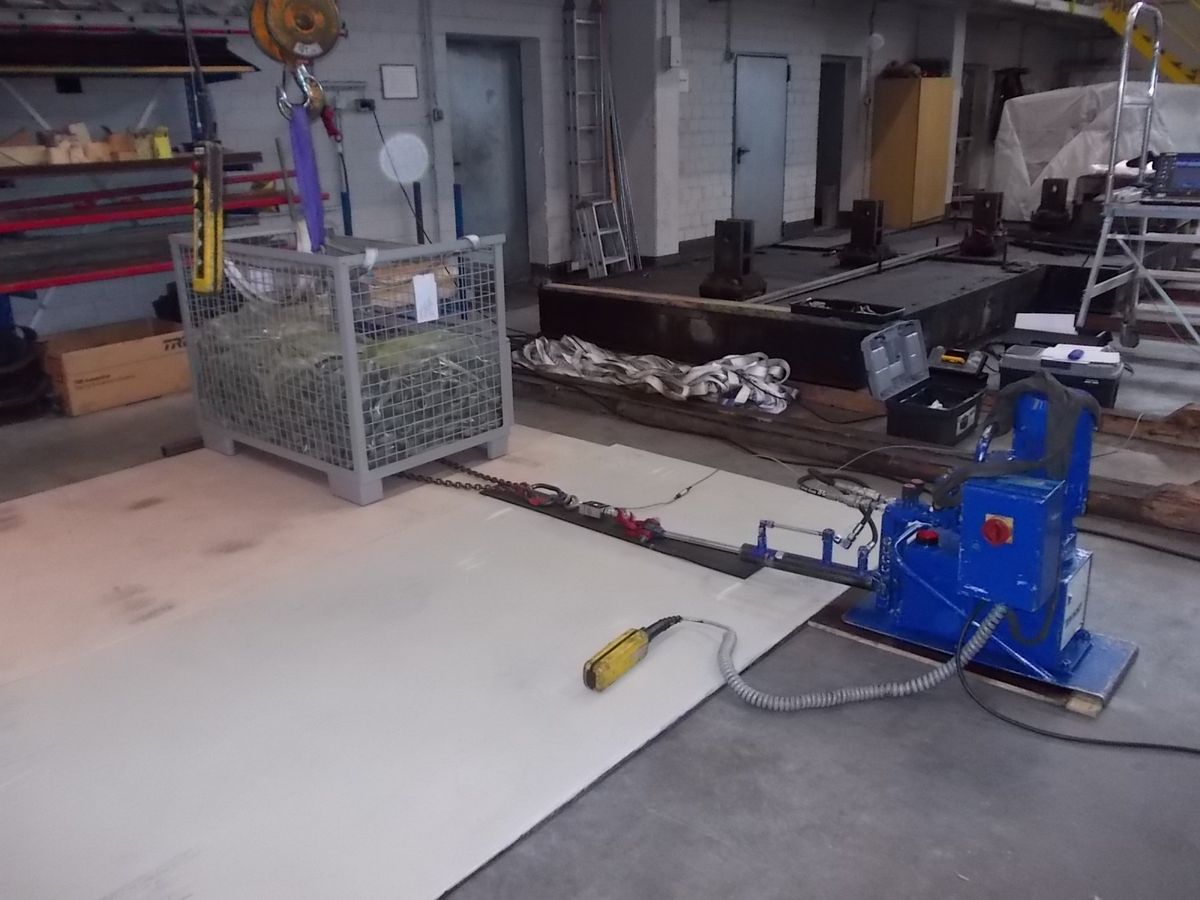

As soon as the measured values are analysed, and when it is proven that the measured sliding friction coefficients in combination with the chosen packing and securing measures lead to a acceptable load securing, TÜV NORD will certify the load securing. Using our mobile test equipment, we can measure the sliding friction coefficient between different friction partners (loading area, cargo carrier, cargo), directly at the customers’ location.

Tel.: +49 511 998-61274

ladungssicherung@tuev-nord.de